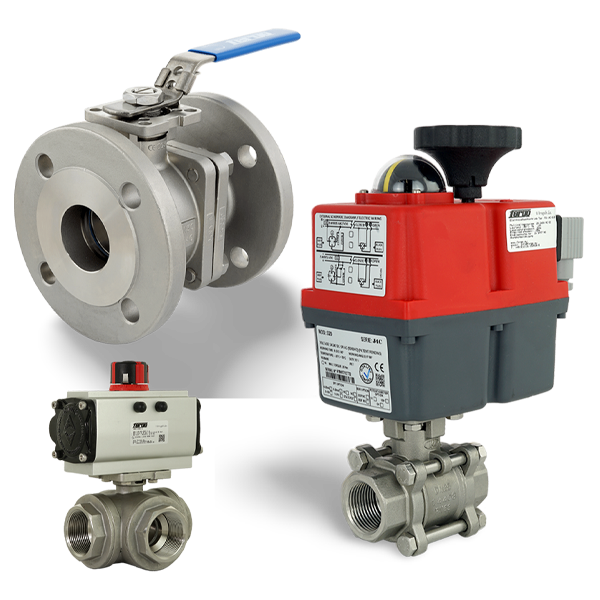

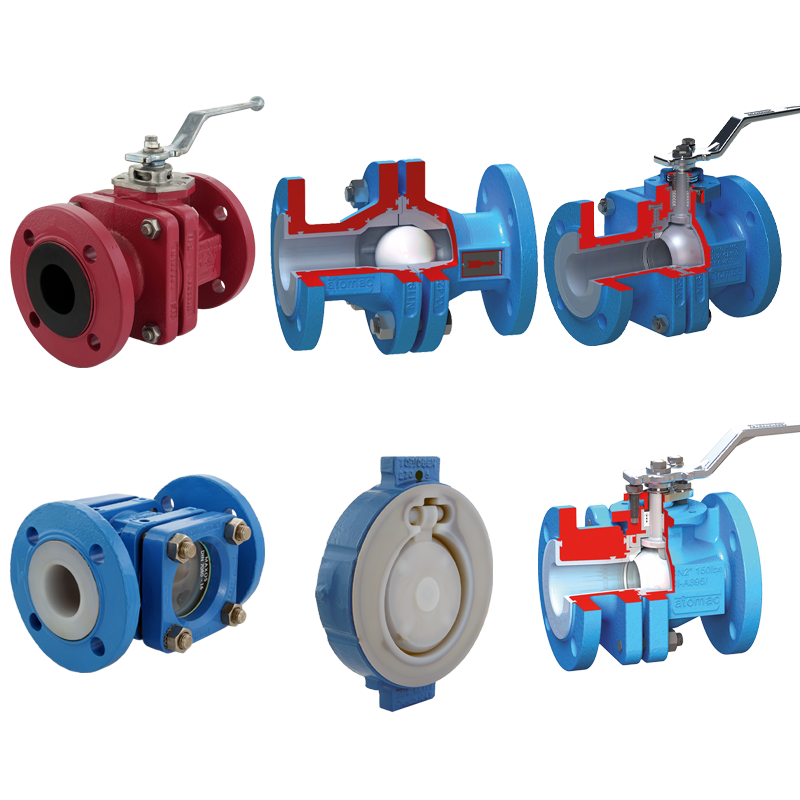

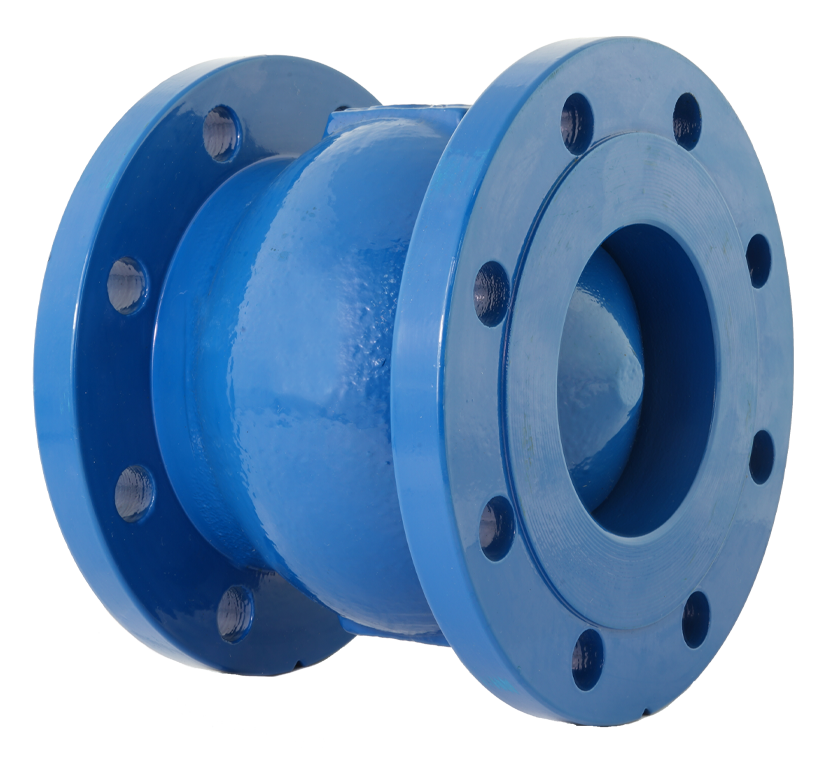

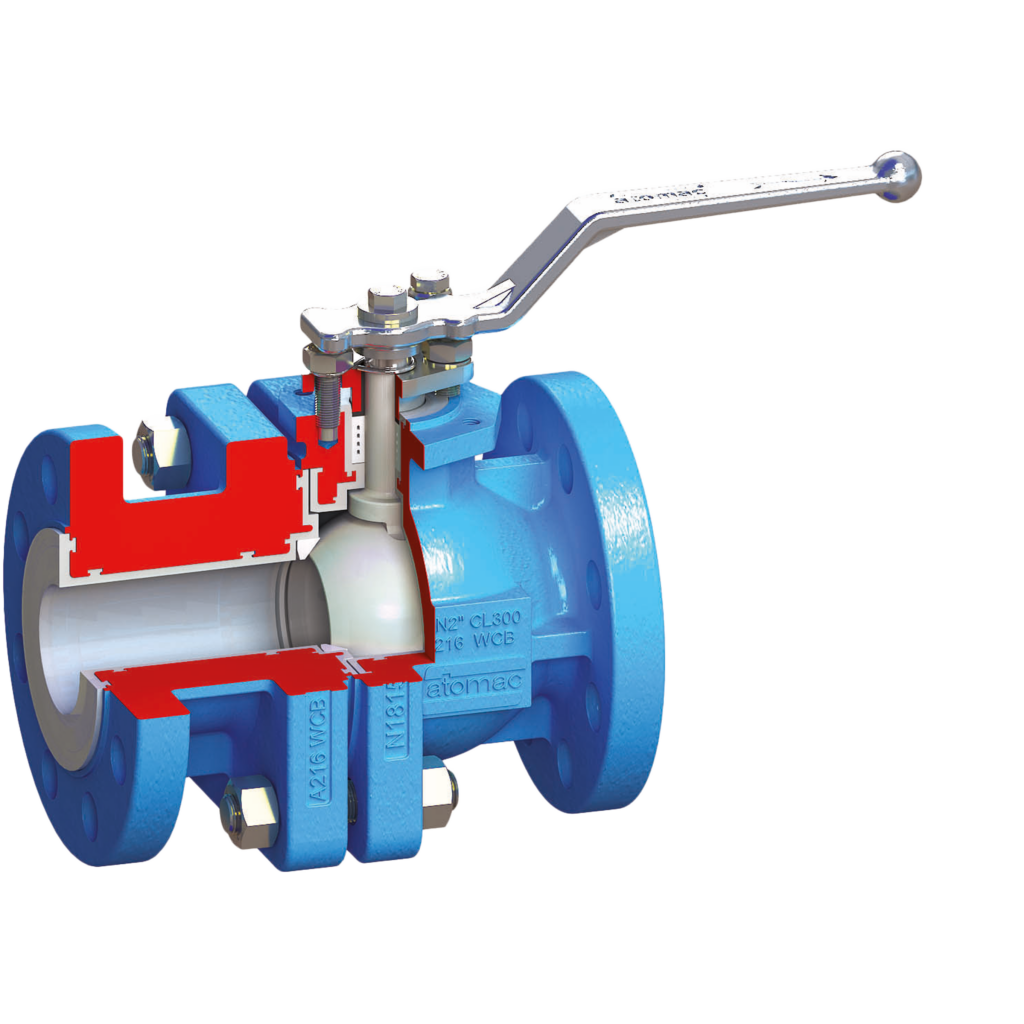

Flowserve Atomac AKH2A: PFA lined ball valve

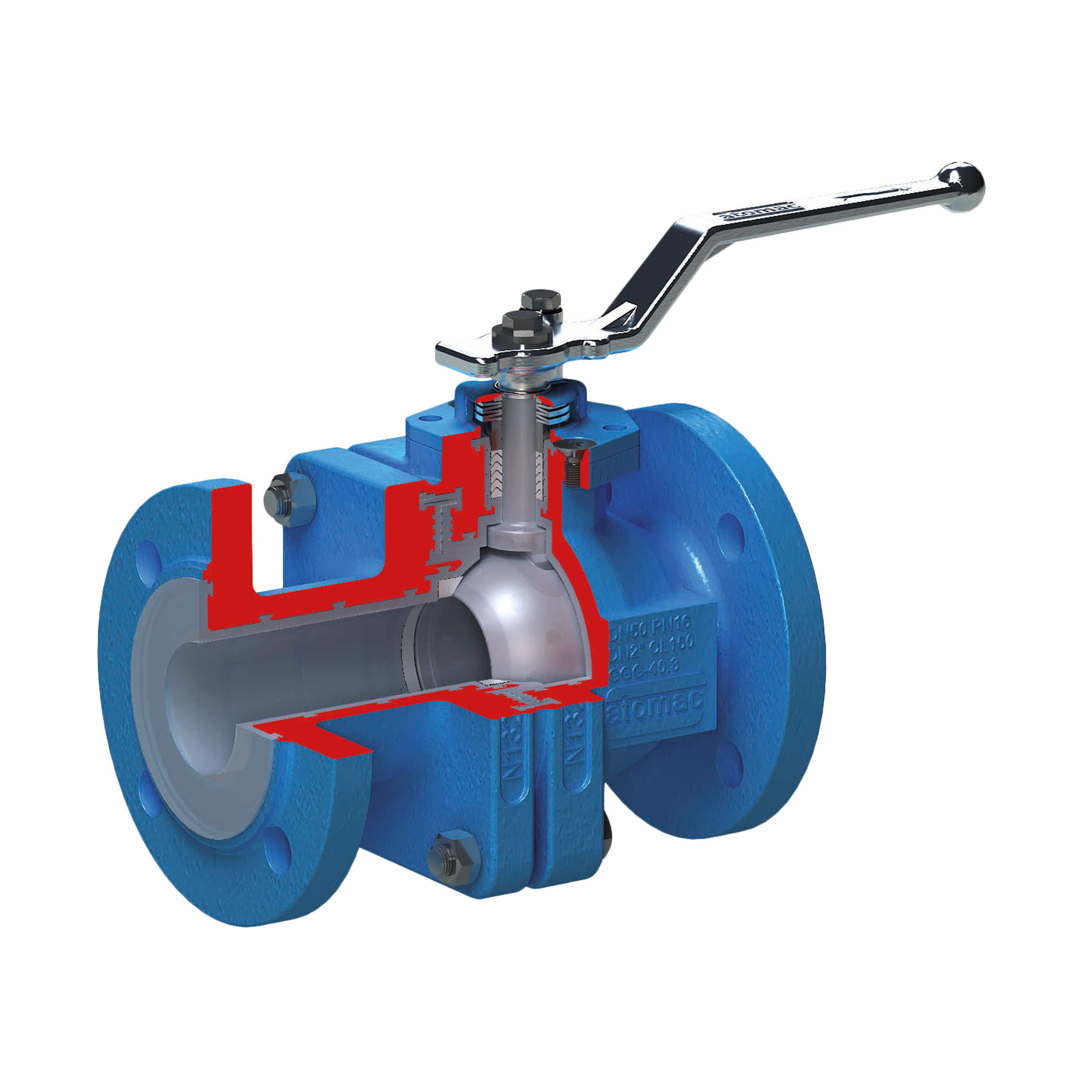

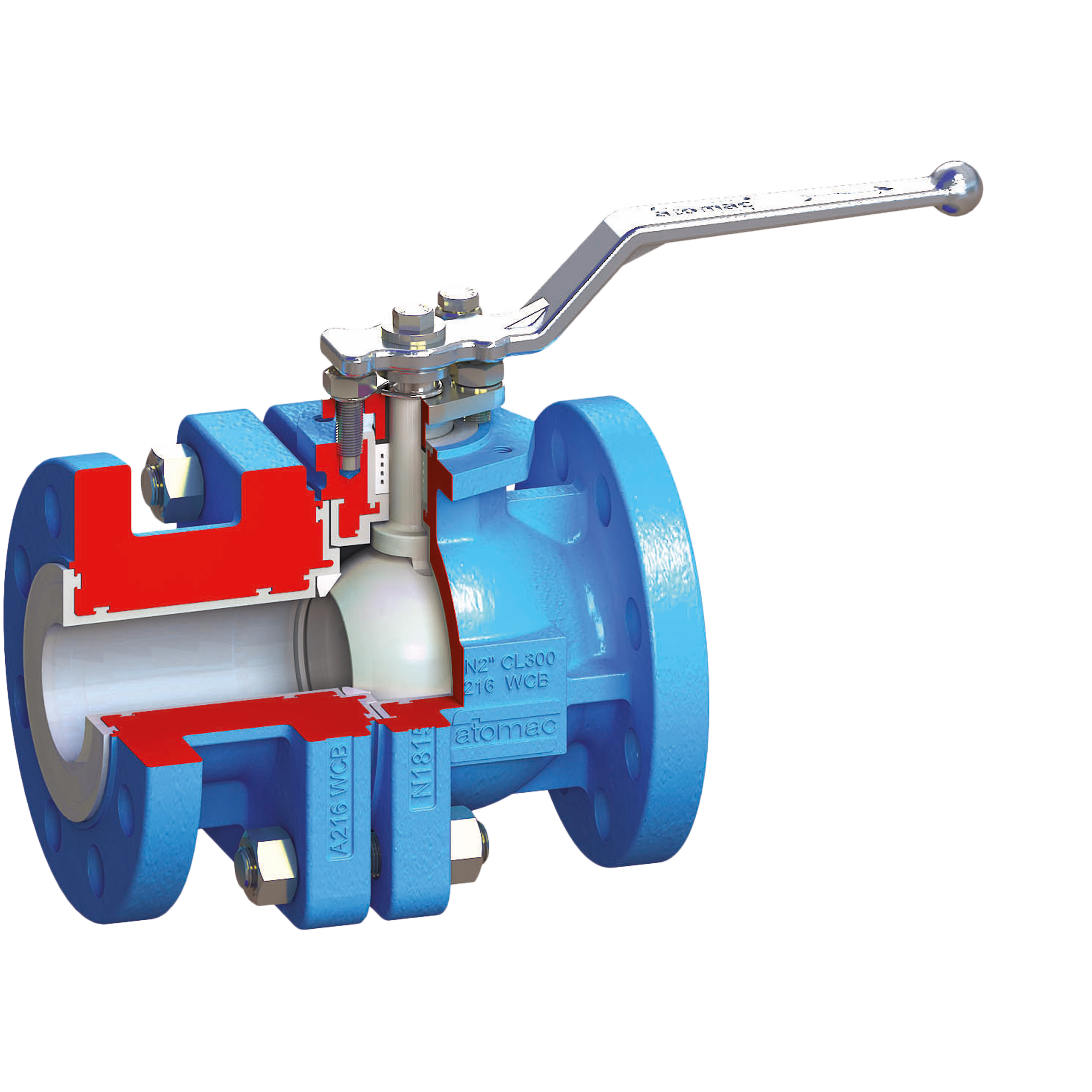

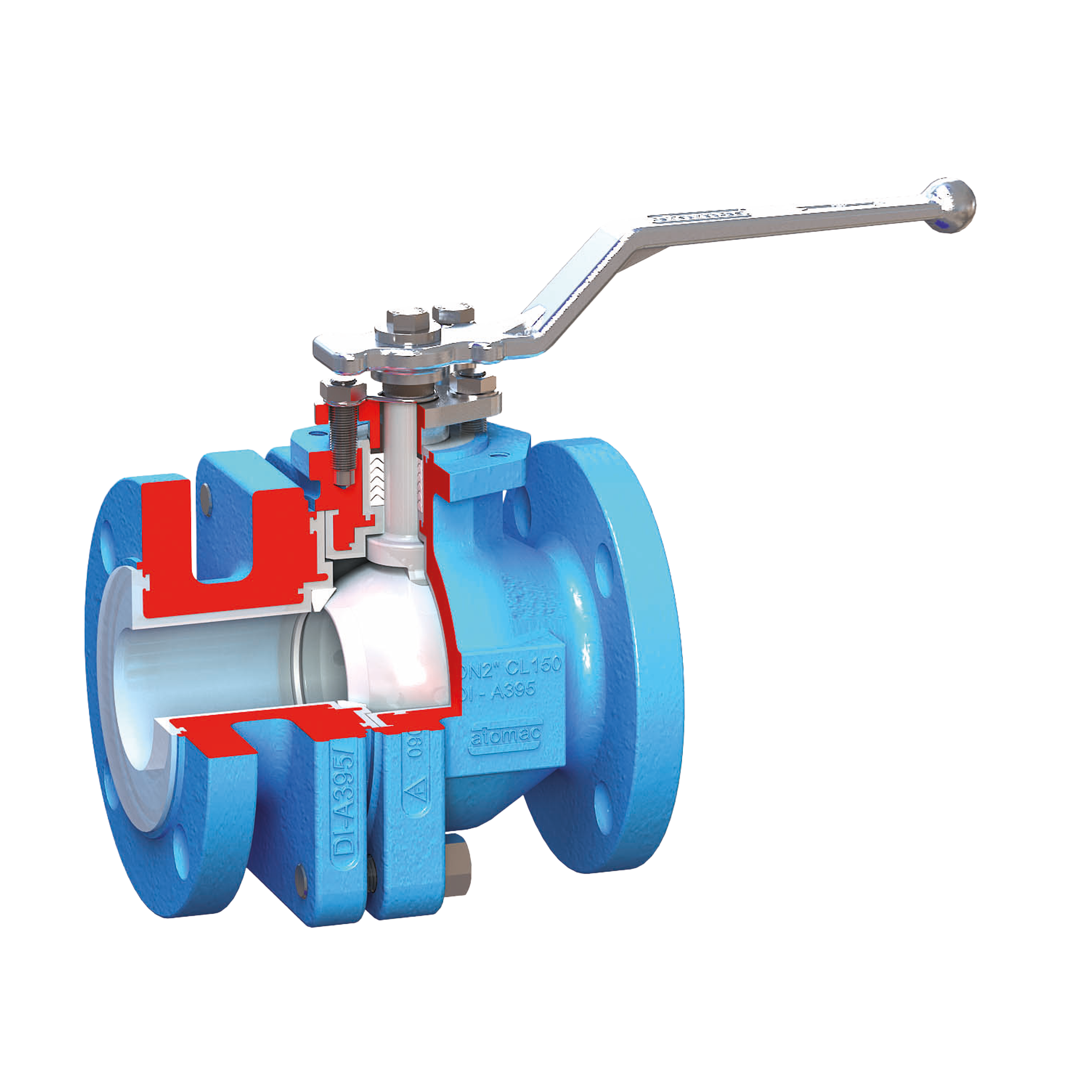

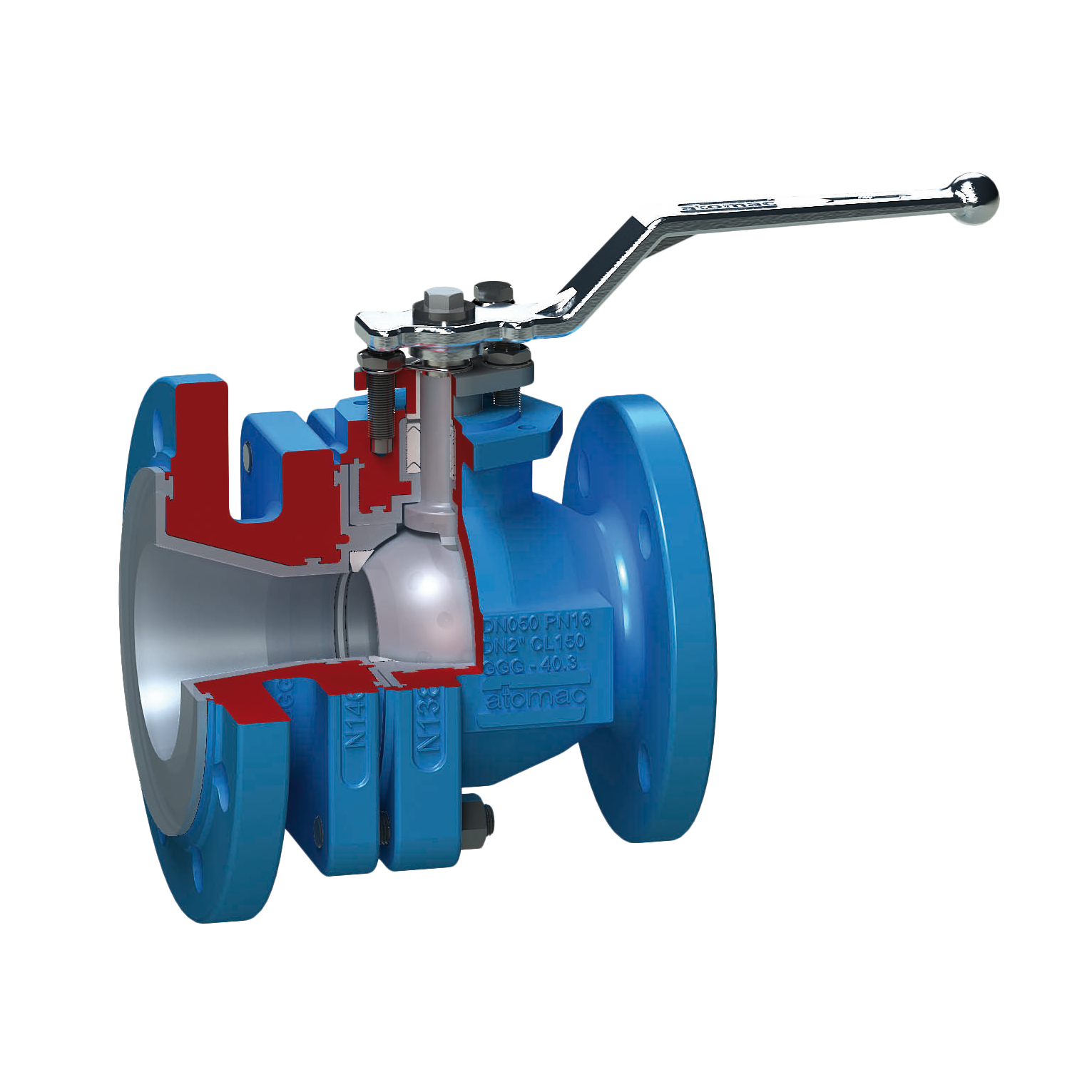

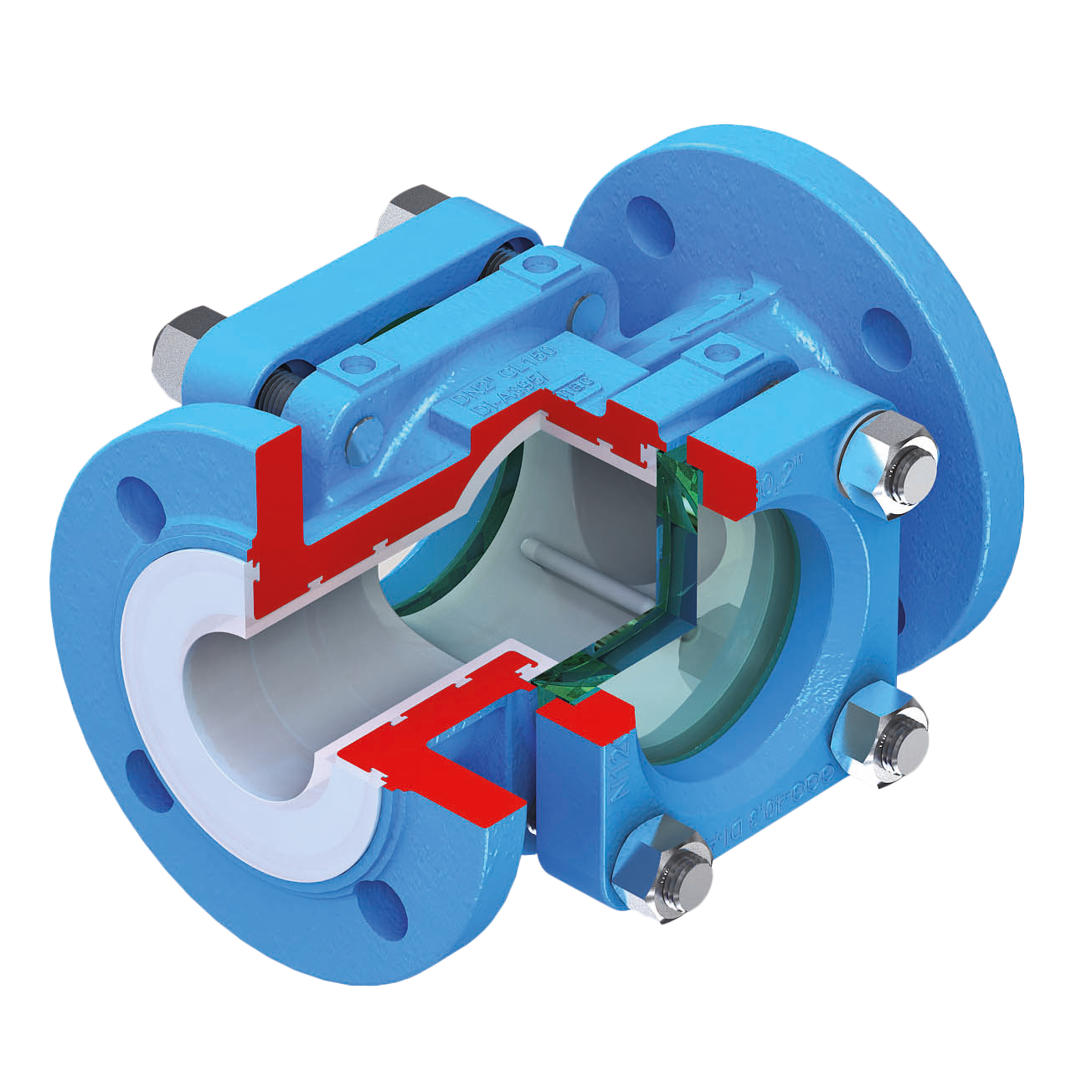

A Flowserve AKH2A is a two-piece full port standard PFA lined ball valve which offers high safety factors, high stability, and rigidity and eliminates a potential leak path. The full port design minimizes pressure losses and increases flow capacities thus reducing energy and pumping costs.

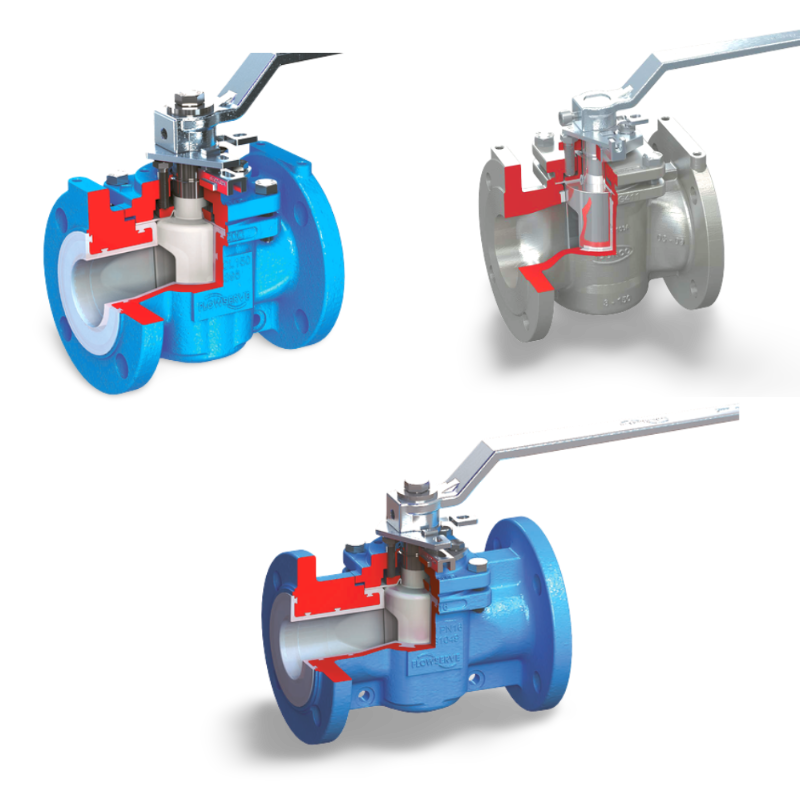

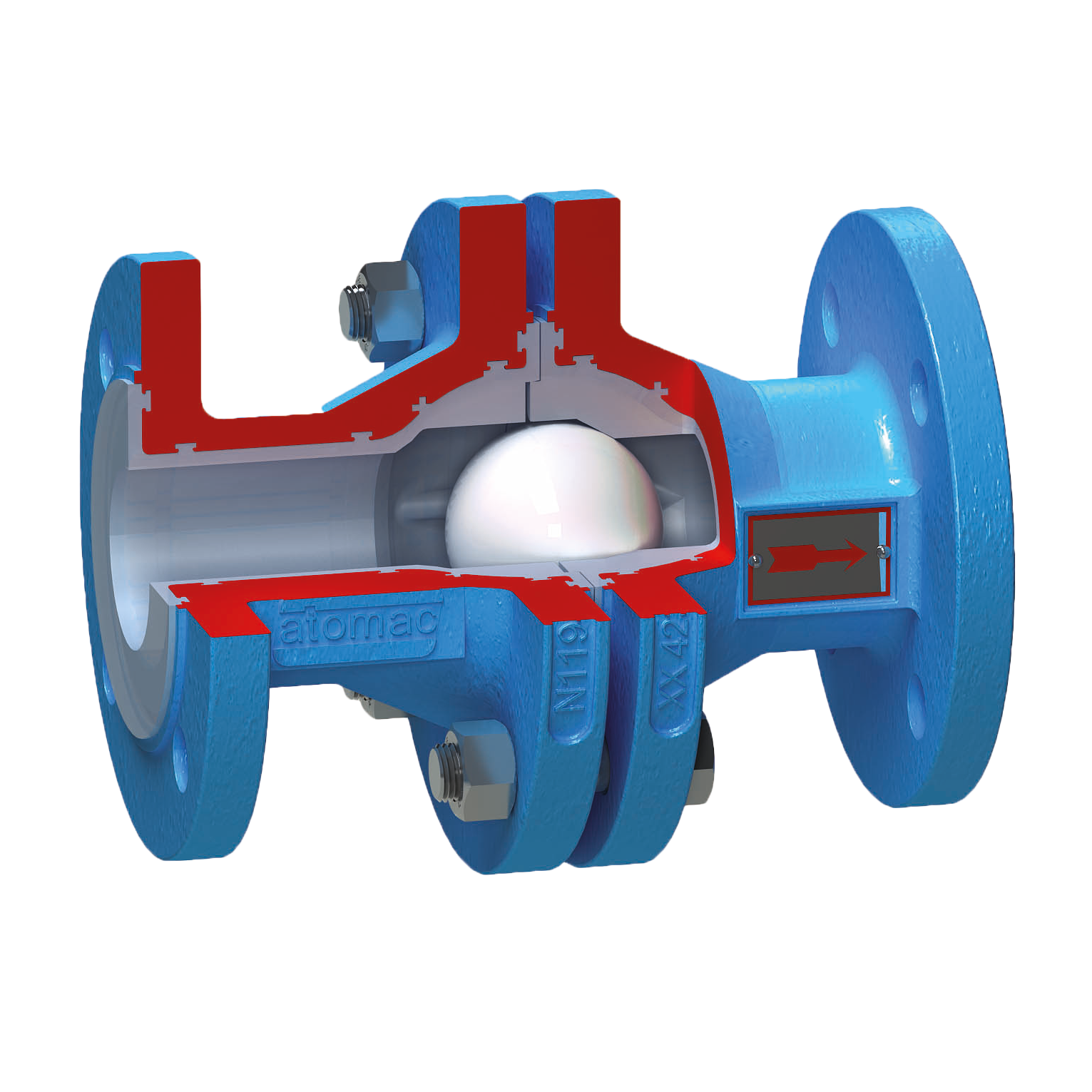

FLOWSERVE ATOMAC lined ball valves are engineered to include a free-floating ball design which offers the following benefits: Low frictional coefficients resulting in low operating torques. Positive shut-off across the pressure range. Reduction of stem side loads eliminating potential leaks to the atmosphere through the valve gland. A real anti-blow-out stem design offers increased safety. Each lined ball valve has its anti-static device, which protects against potentially dangerous electrostatic discharges. Long-life seats, large stem sealing area as well as substantial middle flanges and the moulded liner take care of a leak and trouble-free valve and minimize downtime and maintenance.

Due to the actuator mounting flanges design according to DIN EN ISO 5211, pneumatic, electric or hydraulic actuators can easily be fitted. A wide range of liner materials can be selected from FEP, PFA, Tefzel, PP, PVDF as well as conductive PFA. Also available with a V-port ball for precise modulating control service or with a C-ball available.

Ball valve ATOMAC AKH2 (Art.-Nr.: 100-1103-xx) DN150 (6″), DN200 (8″), DN250 (10″)

- ATOMAC PFA lined, with self-adjusting packing gland

- Full bore design

- Max. operating temperature: +200°C

- Face to face acc. to EN 558, Row 1

- Flanged acc. to DIN EN 1092-2

- Body: ductile iron EN-JS 1049 (GGG40.3) / PFA lined

- Ball: ductile iron EN-JS 1049 (GGG40.3) / PFA coated

- Stem: stainless steel 1.4470 / PFA coated

- Seat rings / packing: PTFE

- Bolting: A2-K70

- Actuation: Handlever (lockable), gearbox, pneumatic & electric actuator

- Accessories and options: Limit switch box, solenoid/pilot valve, positioner, shaft extension/stem extension

Type

Ball Valve

Operations

Electric Actuator, Pneumatic double-acting, Pneumatic single-acting, Lever, Topflange (ISO 5211), Gearbox with Handwheel

Sizes

DN15, DN20, DN25, DN32, DN40, DN50, DN65, DN80, DN100, DN150, DN200, DN250, DN300, 1/2", 3/4", 1", 1 1/2", 2", 3", 4", 6", 8", 10", 12", 14"

Flange connection

PN10, ANSI 150, PN16

Face-to-face

DIN EN 558 Line 1

Body material

GGG40+PFA, GGG40+FEP

Packing gland

PTFE, PTFE+Graphite

Pressure range

PN16

Ball material

PFA coated, FEP coated, Ceramic

Ball seat

PTFE

Lining/Coating

PFA, FEP

Connection

Flanges