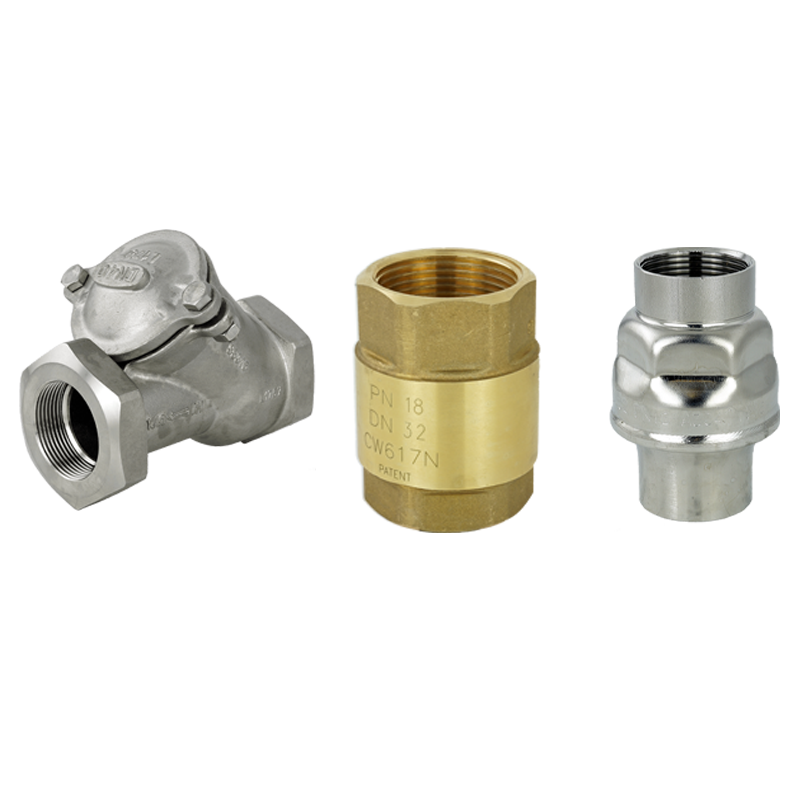

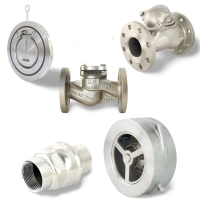

Check Valves

Non-return valves with various materials and connections

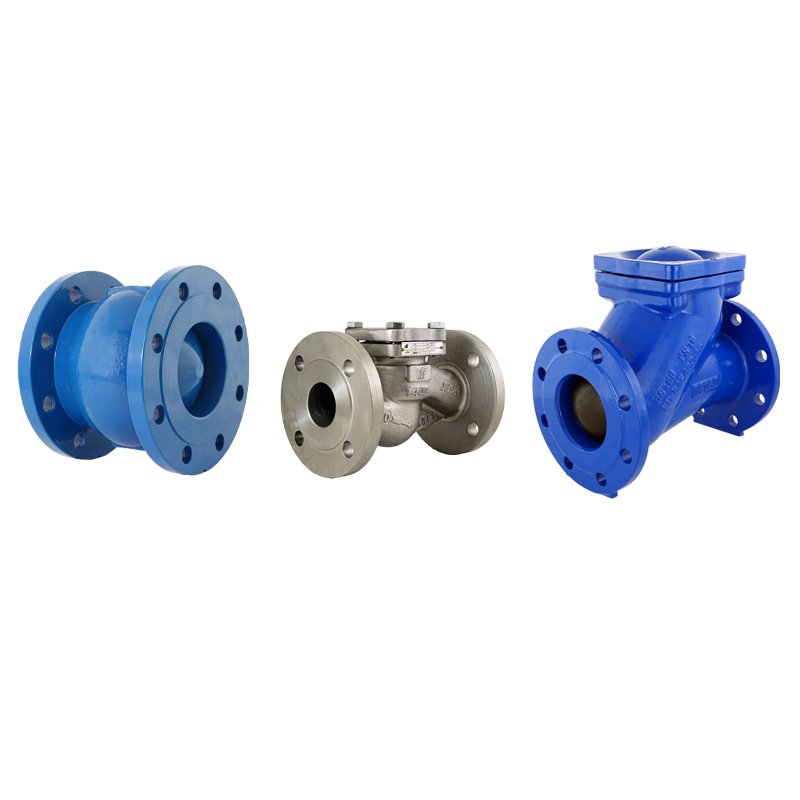

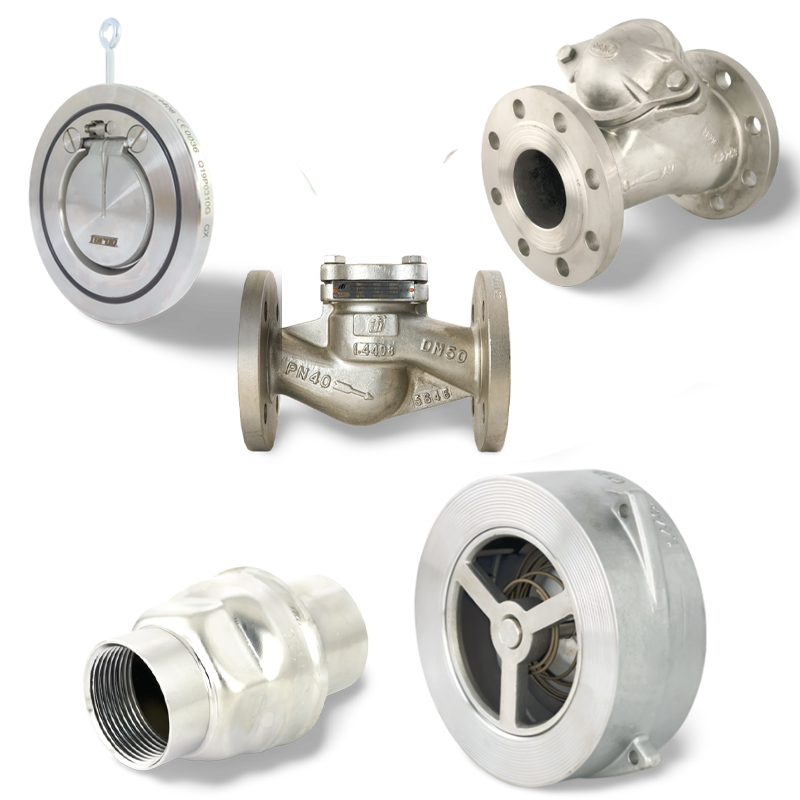

Check valves wafer type and with flanged or threaded ends

Rückschlagklappen und -ventile: Schutz vor Rückfluss

Rückschlagventile und Rückschlagklappen sind essentielle Bestandteile moderner Rohrleitungssysteme. Sie verhindern effektiv den Rückfluss von Medien und schützen so vor Schäden, die durch unkontrollierten Rückfluss entstehen können. Solche Rückflüsse können ernsthafte Probleme wie Korrosion, Verschmutzung oder sogar Systemausfälle verursachen, die den Betrieb unwirtschaftlich machen.

Im Fergo Shop finden Sie eine umfangreiche Auswahl an Rückschlagventilen und Rückschlagklappen aus hochwertigen Materialien wie Edelstahl und Stahl. Hier sind die verschiedenen Produkte von Fergo:

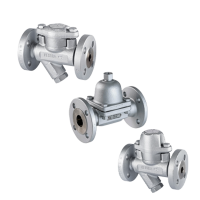

- Gestra Rückschlagventile (RK86, RK86A, RK76, RK70, RK71): Nennweiten DN15–DN100, Druckstufen PN10/16/25/40 und Class150/300. Online im Fergo-Shop bestellbar.

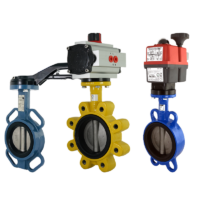

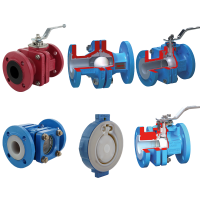

- Rückschlagklappen (RK100, RK101, RK104, RK106): Ausführungen: Gewinde, Zwischenflansch. Materialien: Edelstahl, verzinkter Stahl, PVC-U, PP-H, Messing. Dichtungen: NBR, EPDM, FKM (Viton), PTFE, Metall. Optionen: Mit/ohne Federrückstellung, DN15–DN600.

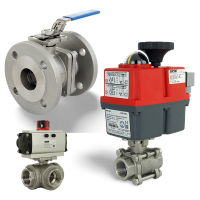

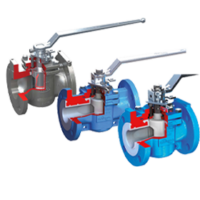

- Rückschlagventile RV108/RV101/ZV116/ZV216: Gehäuse:

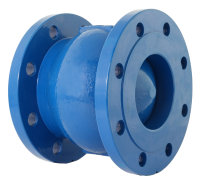

- Kugelrückschlagventile RB105/RB106: Edelstahl/Sphäroguss, Muffen- oder Flanschanschluss.

- Doppelflügel-Rückschlagventile RF200/RF202: Edelstahl/Stahl/Sphäroguss, DN50–DN300.

- Fußventile RV105: Messing, DN15–DN100.

Diese Rückschlagarmaturen kommen in Trinkwasser-, Heizungs-, Abwasser- und Industrieanlagen für mehr Sicherheit und Effizienz zum Einsatz.

Hochwertige Materialien und Dichtungen wie NBR, EPDM, FPM-Viton oder PTFE garantieren Langlebigkeit und Korrosionsbeständigkeit.

Unterschiede zwischen Rückschlagklappen und Rückschlagventilen

- Schließmechanismus: Rückschlagklappen schließen durch Schwerkraft oder Gegendruck, während Rückschlagventile eine Feder verwenden, die ein schnelles Schließen ermöglicht.

- Einbau: Rückschlagklappen benötigen oft eine spezifische Einbaulage, während Rückschlagventile universell einsetzbar sind.

- Druck & Durchfluss: Rückschlagklappen eignen sich für niedrige bis mittlere Drücke, während Rückschlagventile für hohe Drücke und schnelle Schließvorgänge optimiert sind.

- Wartung & Kosten: Rückschlagklappen sind einfacher aufgebaut, wartungsfreundlicher und kostengünstiger. Rückschlagventile sind komplexer, erfordern mehr Wartung und sind teurer.