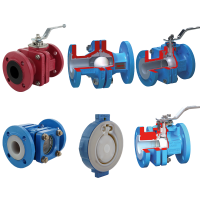

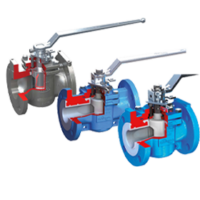

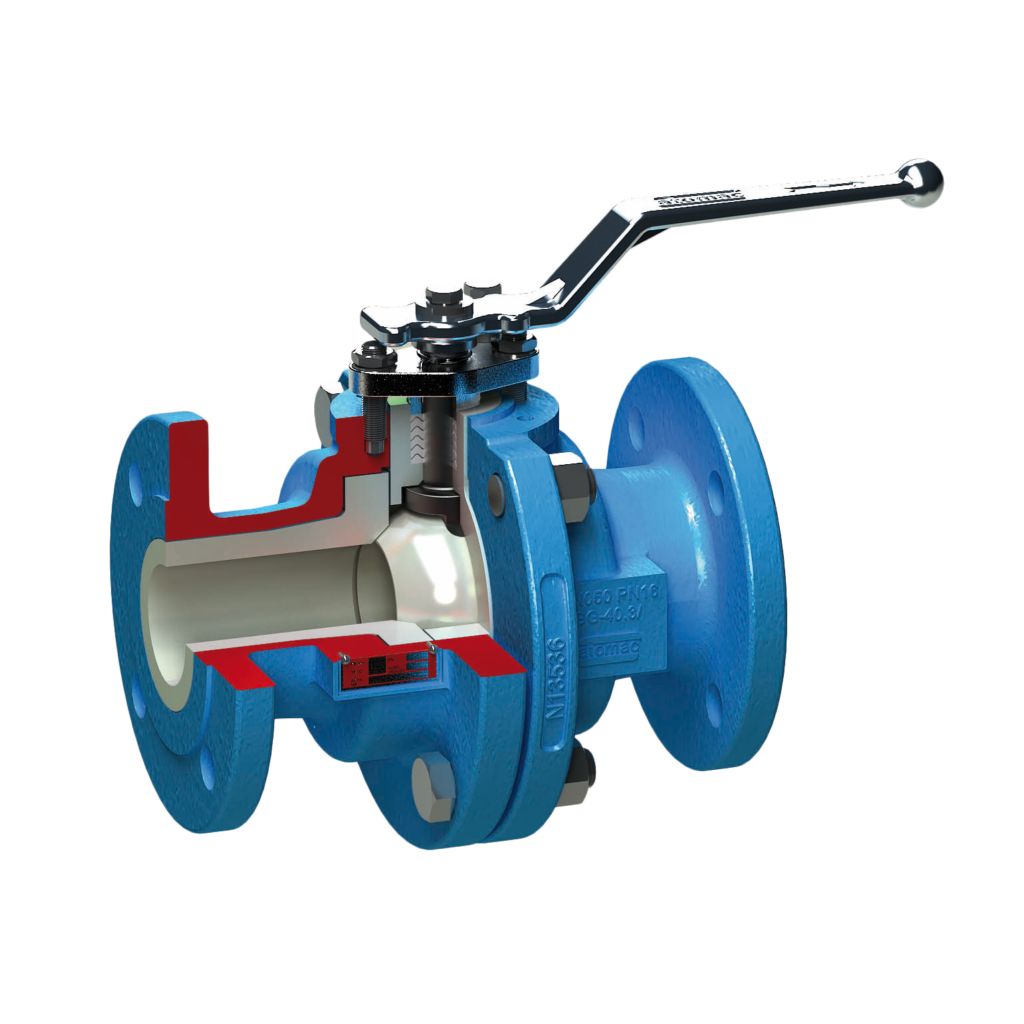

Flowserve Atomac AKH5: Ceramic lined ball-valve

Due to advanced ceramic technology, the AKH5 from FLOWSERVE achieves an unequalled performance that offers the ideal solution for many difficult applications in which wear, abrasion, corrosion and high temperature cause conventional materials to fail. Furthermore the design of the AKH5 offers minimum cavity space that reduces the retention of medium within the body cavity consequently reducing product contamination problems.

Wear Resistance: Abrasive slurries have little effect on its rock hard surfaces.

Corrosion Resistance: It is virtually inert to acid bases and most other corrosives.

Impact Resistance: The composition of the materials and the advanced process technology result in high mechanical strength and toughness.

Temperature Resistance: High operating temperatures and thermal shock are not a problem. The melting point of Mg-PSZ ceramic is well beyond the valve limits of 350°C. Higher ratings on request.

Cavitation Resistance: Cavitation related problems are sharply reduced due to the extreme hardness of the ceramic material (Rockwell 89).

Advantages: The Mg-PSZ ceramics have consistently outperformed steels, cobalt, nickel alloys and other ceramics in a wide range of severe applications such as, steam services, abrasive slurries, fly ash, high temperature corrosives and sand abrasion are only a few of the many conditions where the AKH5 Mg-PSZ lined ball valve has solved serious problems. Also available as V-port ball valve for precise flow control and modulation.

Type

Ball Valve

Operations

Electric Actuator, Pneumatic double-acting, Pneumatic single-acting, Lever, Topflange (ISO 5211), Gearbox with Handwheel

Sizes

DN25, DN40, DN50, DN80, DN100, DN150, 1", 1 1/2", 2", 3", 4", 6"

Flange connection

PN10, ANSI 150, PN16

Face-to-face

DIN EN 558 Line 1

Body material

GGG40+Ceramic

Packing gland

PTFE

Pressure range

PN16, Class 150

Ball material

Ceramic

Lining/Coating

Ceramic

Connection

Flanges