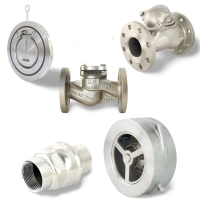

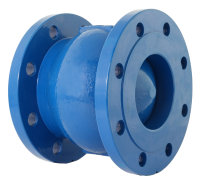

Flow sight glass for demanding applications

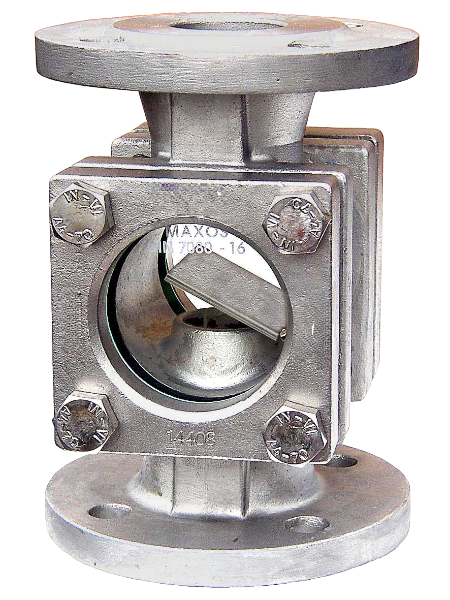

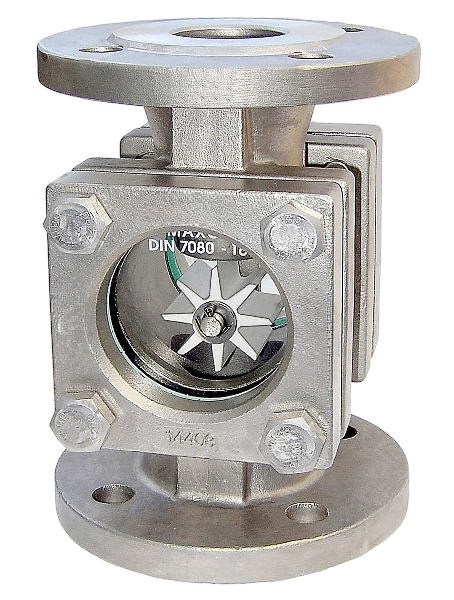

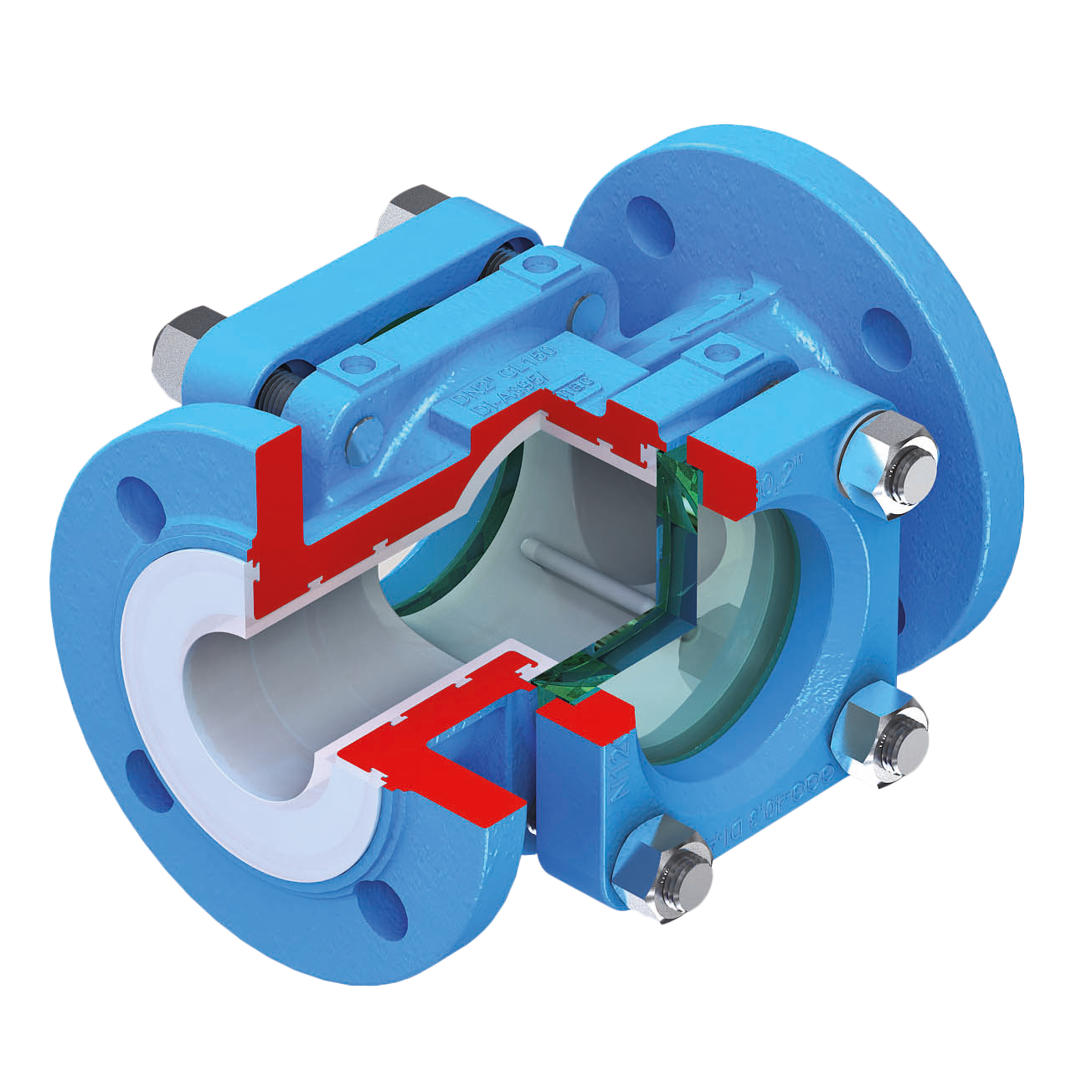

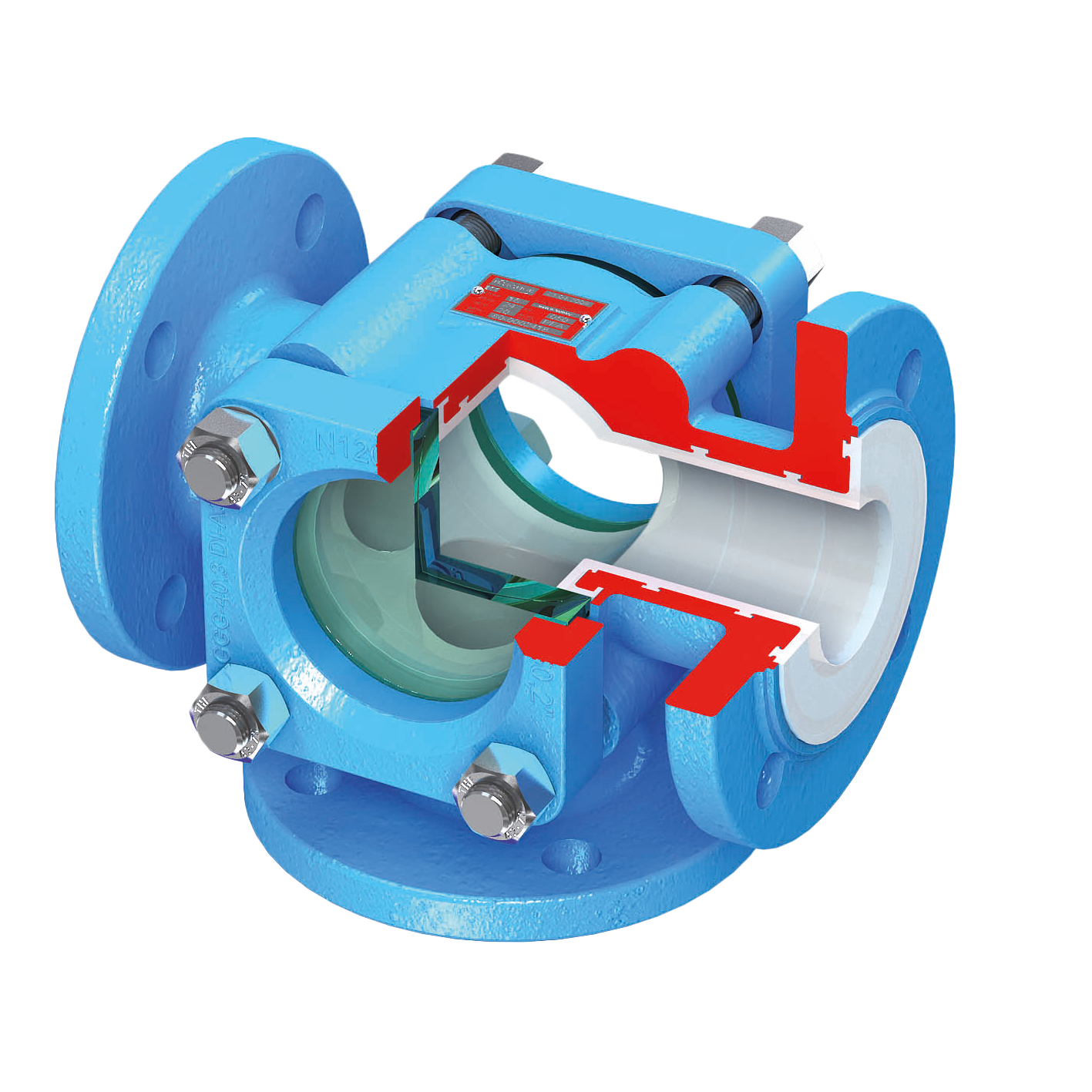

Do you want to know what is flowing through your pipe? The GD200 flow sight glass makes it possible – in a clear and precise way. The sight glass is designed to meet the highest demands and can be used for oil, water, steam, chemicals, acids or bases. Manufactured in accordance with DIN 3237, this sight glass is temperature-resistant up to 280 °C thanks to borosilicate glass as per DIN 7080. Alternatively, it is also available with soda-lime glass – depending on the operating temperature and chemical resistance. Additionally, it comes with graphite seals that remain tight even at higher temperatures.

The GD200 sight glass is available in nominal sizes DN15-DN250, with standard flanges according to DIN PN16, PN25 or PN40. In addition to that, ANSI/ASME Class 150/300 is also available upon request. We can offer these flow sight glasses with bodies made of stainless steel (1.4408/Cf8M), cast steel (1.0619/GS-C25) and gray cast iron (GG25/EN-GJL-250), making them suitable for a wide range of gaseous/liquid media and operating conditions in industry and pipelines.

When it comes to tough applications in the pipelines and industries, the Fergo sight glass type GD200 offers the ultimate performance.

Special executions for the flow sight glass type GD200

- special materials

- with weld-ends

- Sight glass lights (Standard or ATEX version)

- with heating jacket

- with PTFE or plastic rotor/spinner

- with flap

- protective grid

- spraying device

- double glass

- 3-way sight glass

- angle- or multi-way version

Standard executions for the flow sight glass type GD200

Stainless-steel sight glass type GD200, PN10/16 (Product Nr.: 350-1071-xx)

- DN15, DN20, DN25, DN32, DN40, DN50, DN65, DN80, DN100, DN125, DN150, DN200, DN250

- Design acc. to DIN 3237, with drip nose

- Flanged ends acc. to EN 1092-1, PN16

- Face to face acc. to EN 558-1, Line 1 (F1)

- Body: 1.4408

- Glass: borosilicate acc. to DIN 7080 (up to 280°C)

- Gasket: graphite

- Max. working pressure: 16 bar

Flanged sight glass type GD200, PN10/16 (Artikel Nr.: 350-1051-xx)

- DN15, DN20, DN25, DN32, DN40, DN50, DN65, DN80, DN100, DN125, DN150, DN200, DN250

- Ausführung nach DIN 3237, mit Tropfnase

- Flanschanschluss nach EN 1092-1, PN16

- Baulänge nach EN 558-1, Reihe 1 (F1)

- Gehäuse: GS-C 25 (1.0619)

- Glas: Borosilikat nach DIN 7080 (bis 280°C)

- Dichtungen: Grafit

- Max. Betriebsdruck: 16 bar

Stainless-steel sight glass type GD200, PN40 (Artikel Nr.: 350-1081-xx)

- DN15, DN20, DN25, DN32, DN40, DN50, DN65, DN80, DN100, DN125, DN150, DN200, DN250

- Design acc. to DIN 3237, with drip nose

- Flanged ends acc. to EN 1092-1, PN40

- Face to face acc. to EN 558-1, Line 1 (F1)

- Body: 1.4408

- Glass: borosilicate acc. to DIN 7080 (up to 280°C)

- Gasket: graphite

- Max. working pressure: 40 bar

Flanged sight glass type GD200, PN40 (Artikel Nr.: 350-1061-xx)

- DN15, DN20, DN25, DN32, DN40, DN50, DN65, DN80, DN100, DN125, DN150, DN200, DN250

- Sight glass type GD200, PN40-DN15

- Design acc. to DIN 3237, with drip nose

- Flanged ends acc. to EN 1092-1, PN40

- Face to face acc. to EN 558-1, Line 1 (F1)

- Body: GS-C 25 (1.0619)

- Glass: borosilicate acc. to DIN 7080 (up to 280°C)

- Gasket: graphite

- Max. working pressure: 40 bar

Type of products

Flanged sight glass, Flow sight glass

Nominal diameter

DN15, DN20, DN25, DN32, DN40, DN50, DN65, DN80, DN100, DN125, DN150, DN200, DN250

Nominal pressure

PN10, PN16, PN25, PN40, ANSI/ASME Class 150/300

Materials

Stainless-steel, cast-steel, cast iron, special materials

Seal

Graphite

Glass

Borosilicate glass according to DIN 7080 (upto 280°C), soda-lime glass according to DIN 8902