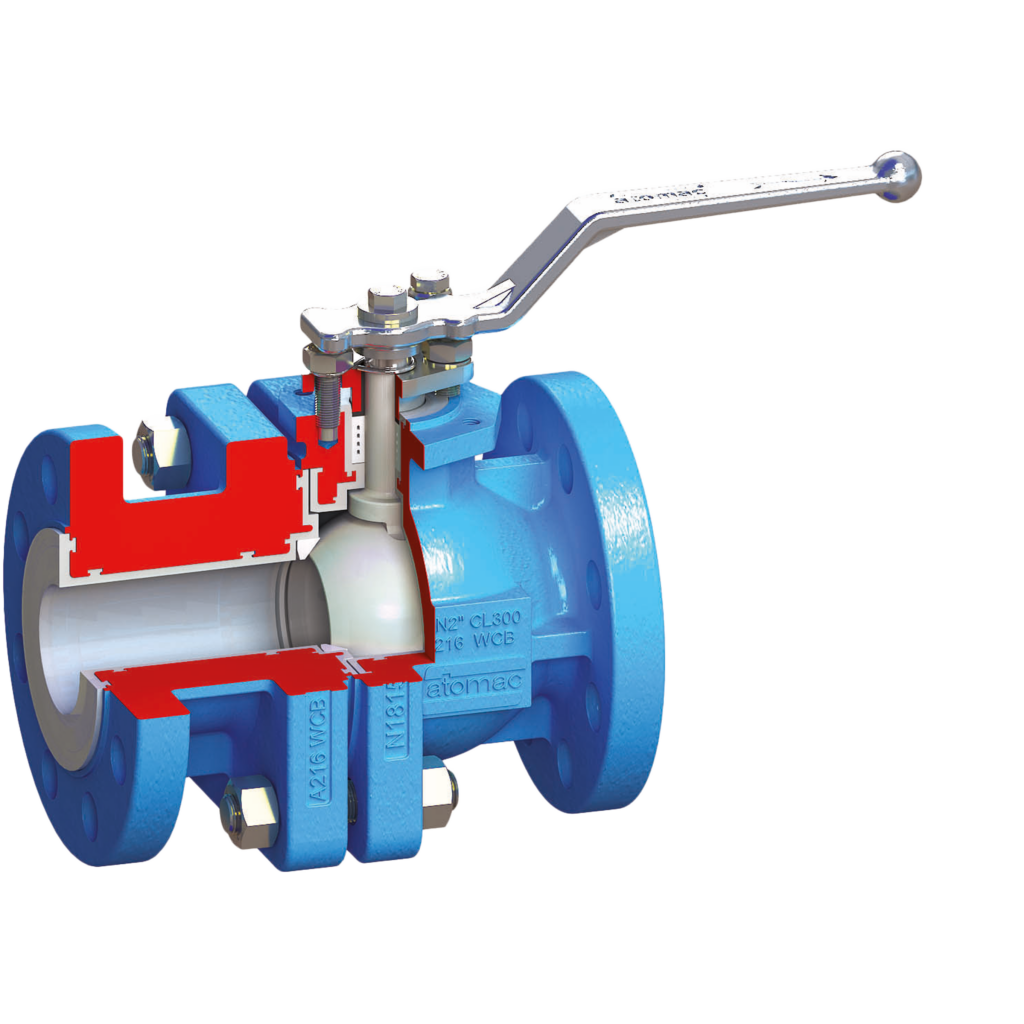

Flowserve Atomac AKH2 Kugelhahn

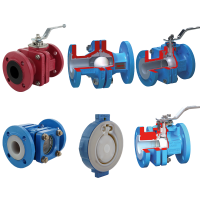

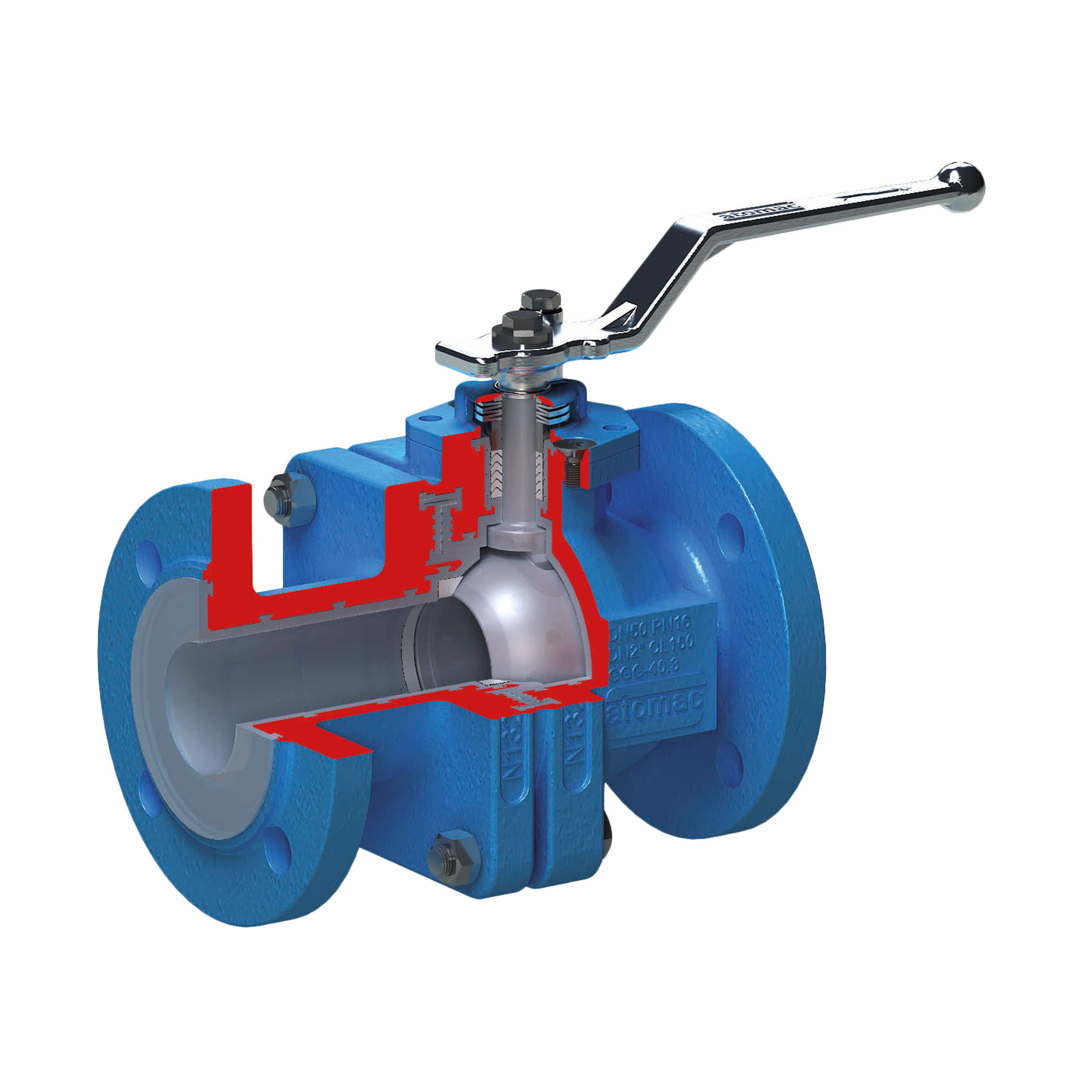

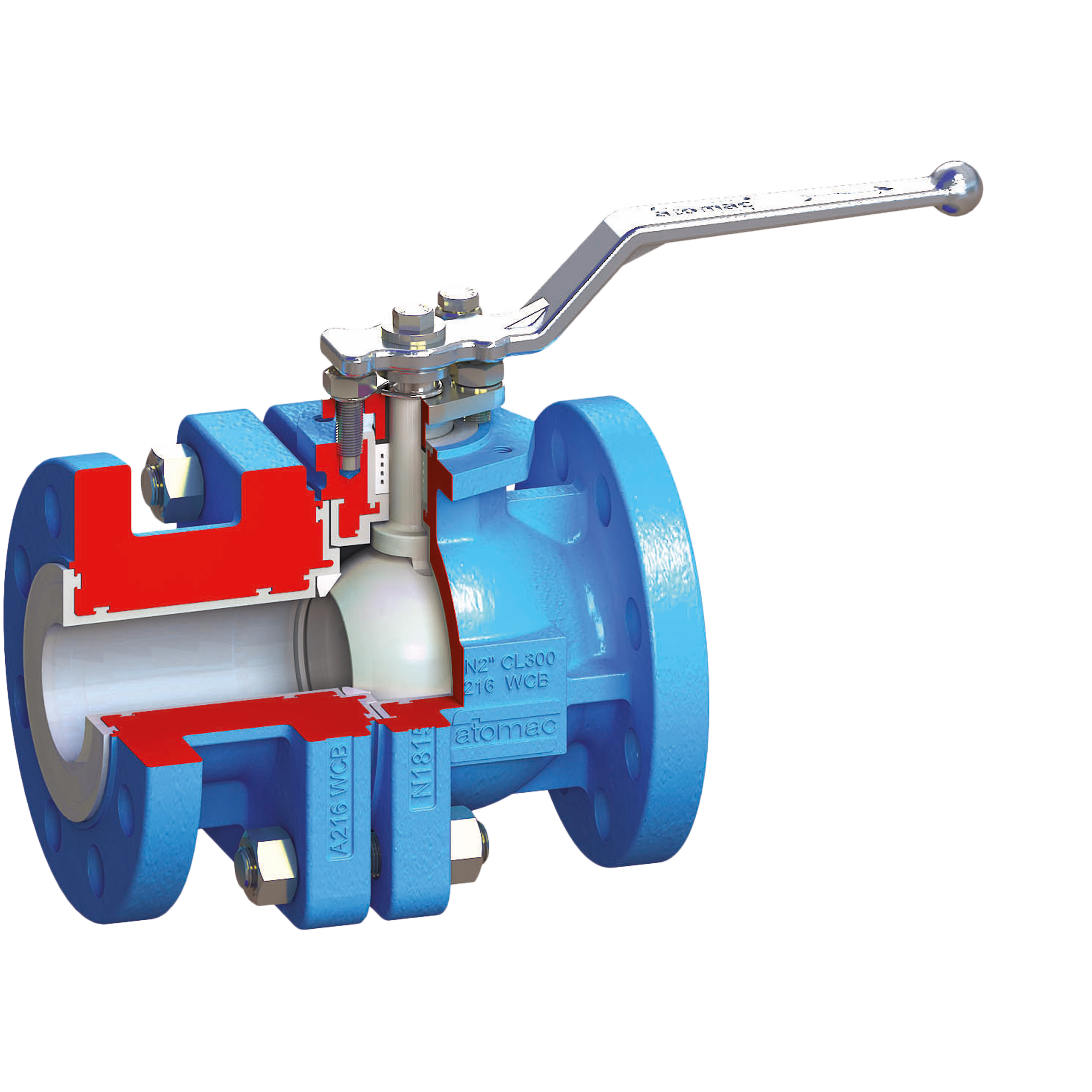

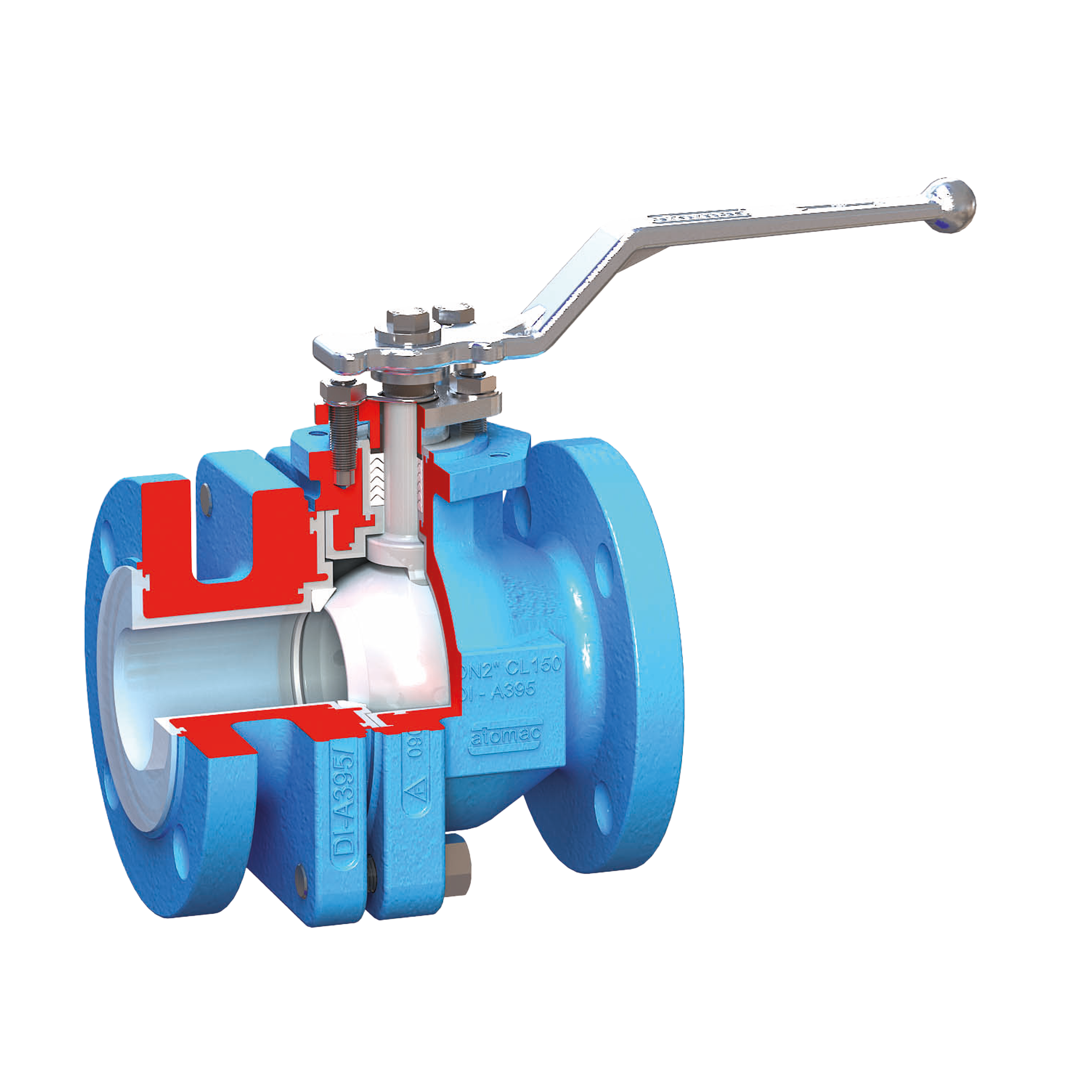

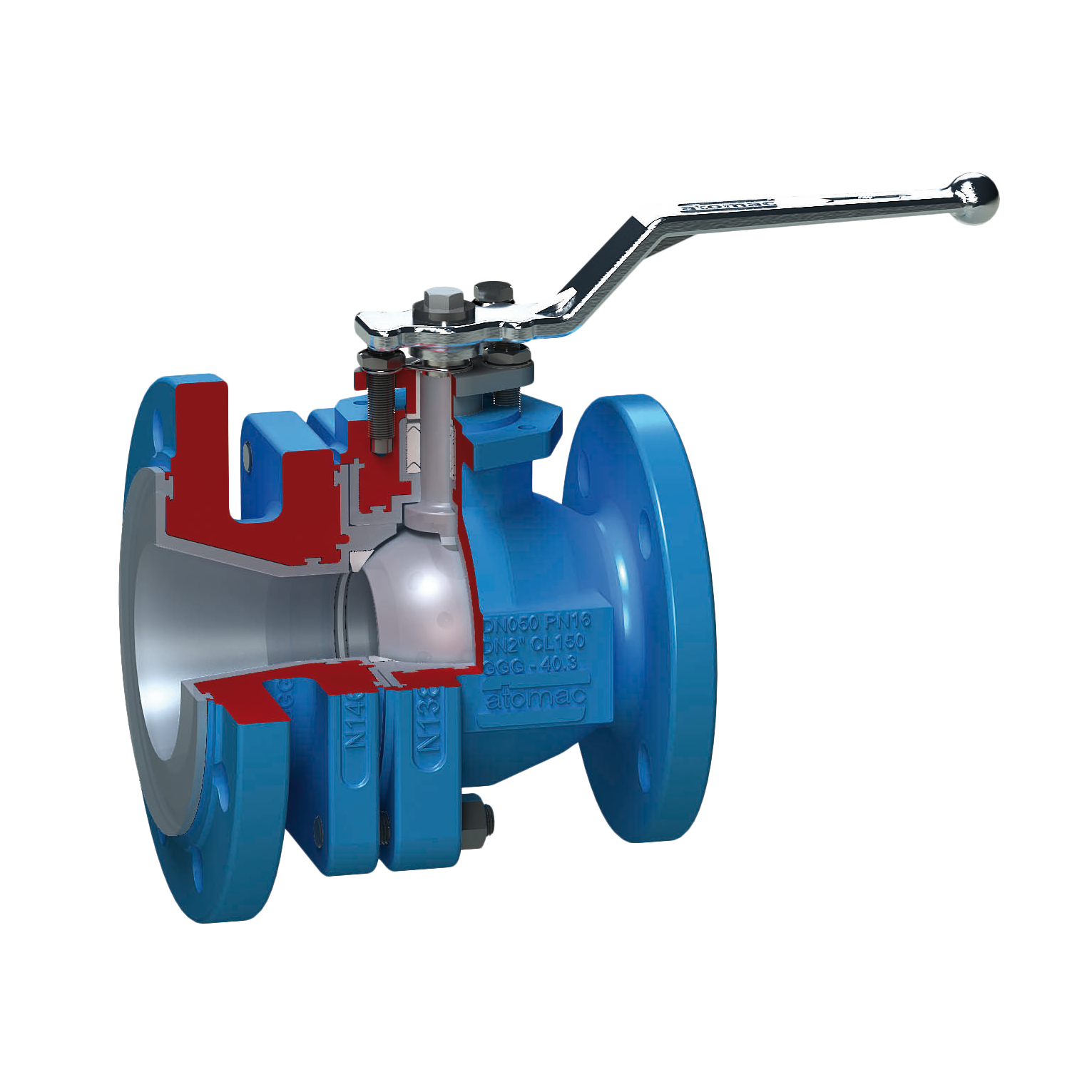

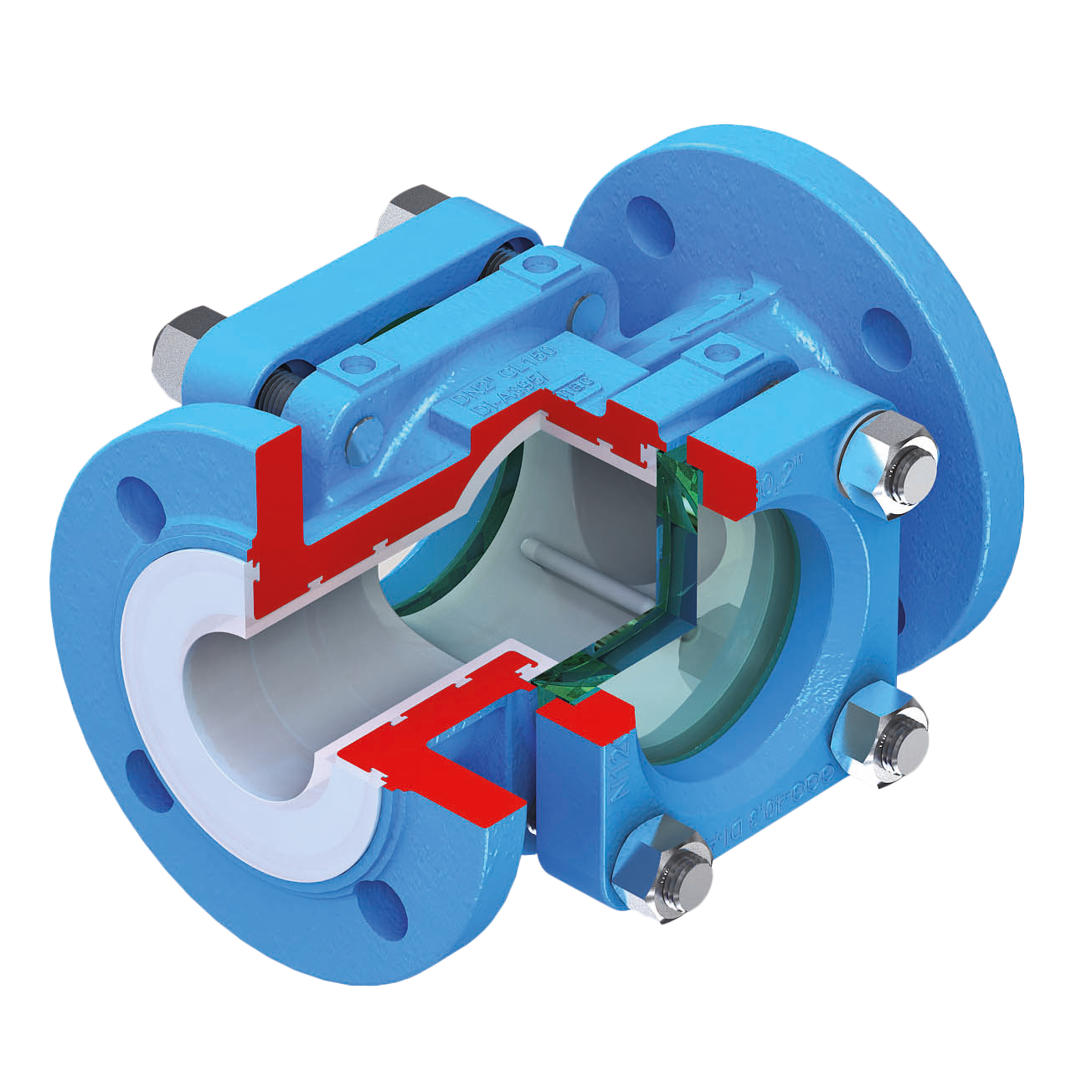

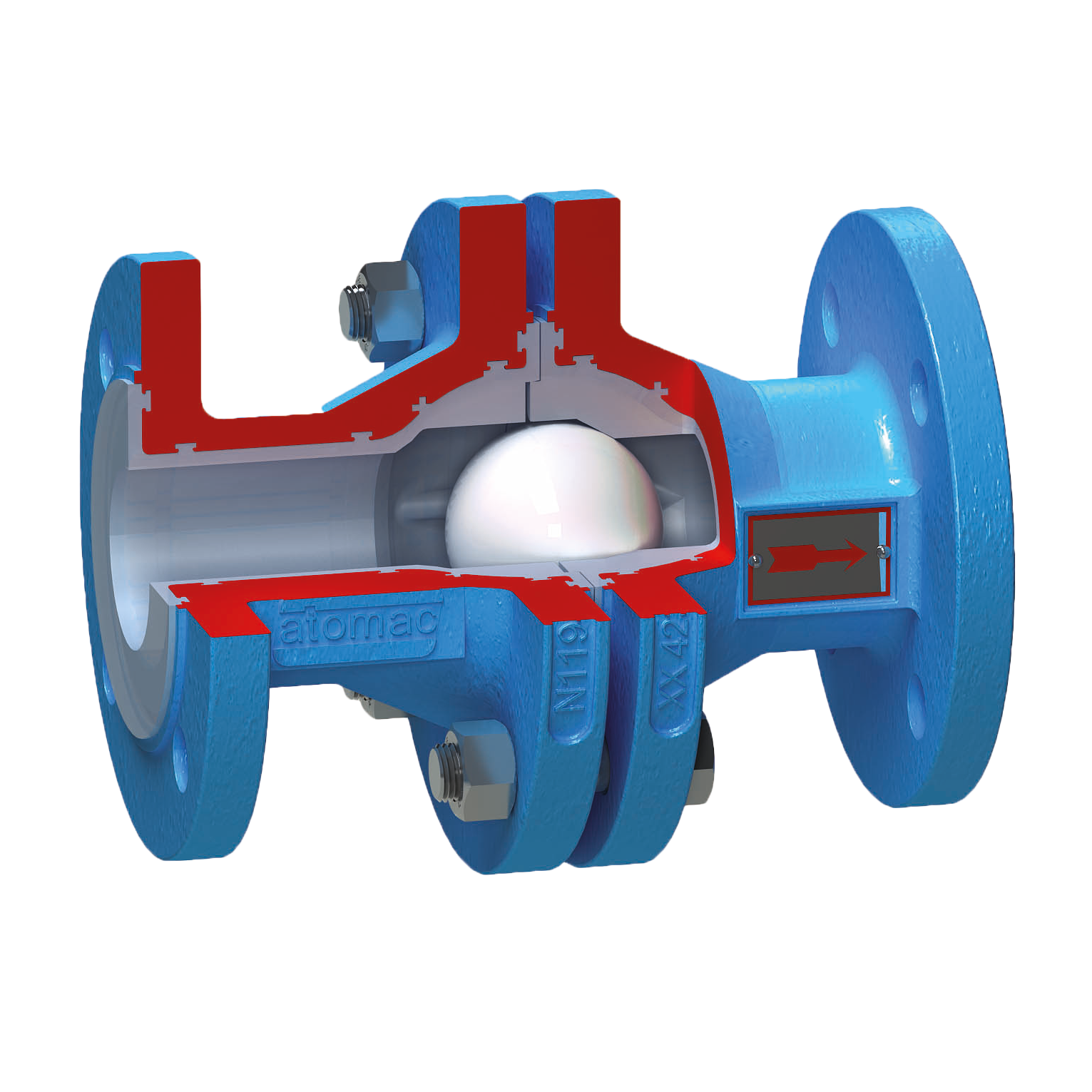

Der FLOWSERVE ATOMAC AKH ist ein zweiteiliger ausgekleideter (z.B. PFA) Kugelhahn mit vollem Durchgang, bietet hohe Sicherheitsfaktoren, Stabilität, Rigidität und eliminiert dazu einen potenziellen Leckageweg. Durch den vollen Durchgang der Armatur werden Druckverluste minimiert und die Durchflusskapazitäten erhöht, dadurch verringern sich Energie- und Pumpkosten.

Die Konstruktion mit einer schwimmend gelagerten Kugel garantiert blasendichte Absperrung über den gesamten Druckbereich. Die schwimmende Lagerung verringert die Schaftbelastung und erhöht die Wirksamkeit und Lebensdauer der Schaftabdichtung. Eine echte ausblassichere Schaftkonstruktion bietet erhöhte Sicherheit. Jeder ausgekleidete Kugelhahn FLOWSERVE ATOMAC AKH2 ist mit einer Antistatik-Vorrichtung versehen, die vor potentiell gefährlichen elektrostatischen Entladungen schützt. Langlebig und optimal dimensionierte Sitzringe, großer Schaftdichtbereich wie auch die mit großen Dichtflächen ausgekleideten Mittelflansche sorgen für eine problemlose Armatur ohne Undichtigkeiten und minimieren die Ausfall- und Wartungszeiten.

Durch die Konstruktion mit einem Aufbauflansch nach DIN EN ISO 5211 ist die Montage von pneumatischen, elektrischen oder hydraulischen Stellantrieben standardisiert. Das Auskleidungsmaterial kann aus einem breiten Angebot mit FEP, PFA, Tefzel, PP, PVDF wie auch leitendem PFA ausgewählt werden. Auch mit V-Regelkugel zur präzisen Regelungsmodulation oder mit C-Kugel erhältlich.

Kugelhahn AKH2 (Art.-Nr.: 100-1103-xx) DN150 (6″), DN200 (8″), DN250 (10″)

- Ausgekleideter PFA Kugelhahn mit nachstellbarer Stopfbuchspackung

- Voller Durchgang

- Max. Einsatztemperatur +200°C

- Flanschanschluss nach DIN EN 1092-2

- Baulänge DIN EN 558 (Grundreihe 1)

- Gehäuse: GGG40.3 / PFA ausgekleidet

- Kugel: GGG40.3 / PFA ummantelt

- Schaltstift: Edelstahl 1.4470 / PFA ummantelt

- Dichtung Kugel: PTFE

- Packung: PTFE Dachmanschetten

- Verschraubung: A2-K70

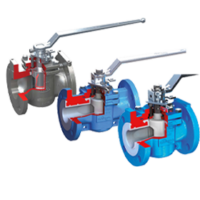

- Betätigung: Handhebel (abschließbar), Getriebe, pneumatischer & elektrischer Antrieb

- Zubehör & Optionen: Endschalterbox, Magnetventil, Stellungsregler, Spindelverlängerung

Produktbezeichnung

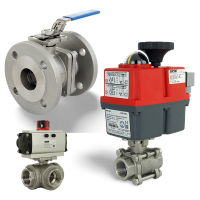

Kugelhahn

Betätigungen

Elektromotor, Pneumatisch doppelwirkend, Pneumatisch einfachwirkend, Handhebel, Aufbauflansch (ISO 5211), Getriebe mit Handrad

Nennweiten

DN15, DN20, DN25, DN32, DN40, DN50, DN65, DN80, DN100, DN150, DN200, DN250, DN300, 1/2", 3/4", 1", 1 1/2", 2", 3", 4", 6", 8", 10", 12", 14"

Flanschanschluss

PN10, ANSI 150, PN16

Baulänge

DIN EN 558 Reihe 1

Gehäusematerial

GGG40+PFA, GGG40+FEP

Stopfbuchspackung

PTFE, PTFE+Grafit

Druckstufe

PN16

Kugelmaterial

PFA beschichtet, FEP beschichtet, Keramik

Kugelsitz

PTFE

Auskleidung

PFA, FEP

Anschluss

Flansche